1. Technical requirements for charging piles

According to the charging method, ev charging piles are divided into three types: AC charging piles, DC charging piles, and AC and DC integrated charging piles. DC charging stations are generally installed on highways, charging stations and other places; AC charging stations are generally installed in residential areas, parking lots, road parking spaces, highway service areas and other locations. According to the requirements of the State Grid Q/GDW 485-2010 standard, the electric car charging pile body should meet the following technical conditions.

Environmental conditions:

(1) Working environment temperature: -20°C~+50°C;

(2) Relative humidity: 5%~95%;

(3) Altitude: ≤2000m;

(4) Seismic capacity: the horizontal acceleration of the ground is 0.3g, the vertical acceleration of the ground is 0.15g, and the equipment should be able to withstand three sine waves acting at the same time, and the safety factor should be greater than 1.67.

Environmental resistance requirements:

(1) The protection level of the ev charger shell should reach: indoor IP32; IP54 outdoors, and equipped with necessary rain and sun protection devices.

(2) Three anti-(moisture-proof, mildew-proof, anti-salt spray) requirements: the protection of the printed circuit board, connectors and other circuits in the charger should be treated with moisture-proof, mildew-proof, and salt-spray protection, so that the charger can operate normally in an outdoor humid and salt-containing environment.

(3) Anti-rust (anti-oxidation) protection: The iron shell of the ev charging station and the exposed iron bracket and parts should take double-layer anti-rust measures, and the non-ferrous metal shell should also have an anti-oxidation protective film or anti-oxidation treatment.

(4) The shell of the ev charging pile shall be able to withstand the impact strength test specified in 8.2.10 in GB 7251.3-2005.

2. The structural characteristics of the sheet metal charging pile shell

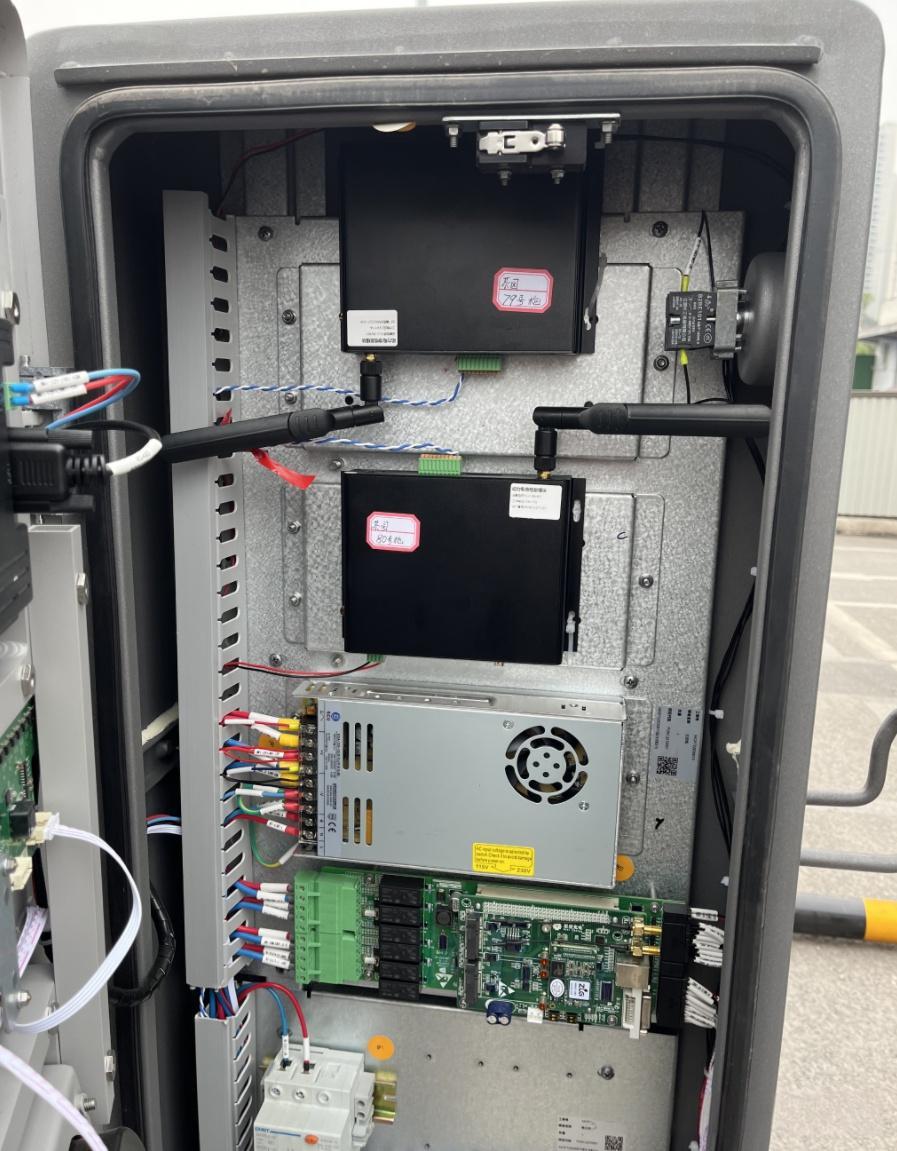

The charging pile is generally composed of a charging pile body, a charging socket, a protection control device, a metering device, a card swiping device, and a human-computer interaction interface, as shown in the figure below.

The sheet metal structure charging pile is made of low-carbon steel plate with a thickness of about 1.5mm, and the processing method adopts sheet metal tower punching, bending, and welding forming process. Some types of charging piles are designed with a double-layer structure in consideration of the needs of outdoor protection and heat insulation. The overall shape of the product is mainly rectangular, the frame is welded as a whole, in order to ensure the beauty of the appearance, the rounded surface is added locally, and in order to ensure the overall strength of the electric vehicle charging piles, it is generally welded with stiffeners or reinforcing plates.

The outer surface of the pile is generally arranged with panel indicators, panel buttons, charging interfaces and heat dissipation holes, etc., the rear door or side is equipped with an anti-theft lock, and the pile is fixed on the installation base by anchor bolts.

Fasteners are generally made of electro-galvanized or stainless steel. In order to ensure that the electric car charger station body has a certain corrosion resistance, the charging pile is generally sprayed with outdoor powder coating or outdoor paint as a whole to ensure its service life.

3. Anti-corrosion design of sheet metal structure charging pile

(1) The appearance of the pile structure of the charging pile should not be designed with sharp corners.

(2) It is recommended that the top cover of the ev charging pile has a slope of more than 5° to prevent water accumulation on the top.

(3) Dehumidifier is used for dehumidification of relatively sealed products to prevent condensation. For products that have heat dissipation needs and open heat dissipation holes, humidity controller + heater should be used for dehumidification to prevent condensation.

(4) After sheet metal welding, the outdoor environment is fully considered, and the external weld is fully welded to ensure that the product meets the IP54 waterproof requirements.

(5) For sealed welded structures such as door panel stiffeners, spraying can not enter the inside of the sealing structure, and the design is improved by means of spraying and assembly, or galvanized sheet welding, or electrophoresis and spraying after welding.

(6) The welded structure should avoid narrow gaps and narrow spaces that cannot be entered by spray guns.

(7) The heat dissipation holes should be designed as components as far as possible to avoid narrow welds and interlayers.

(8) The purchased lock rod and hinge should be made of 304 stainless steel as far as possible, and the neutral salt spray resistance time should not be less than 96h GB 2423.17.

(9) The nameplate is fixed with waterproof blind rivets or adhesive paste, and waterproof treatment must be done when it needs to be fixed with screws.

(10) The selection of all fasteners should be treated with zinc-nickel alloy plating or 304 stainless steel, zinc-nickel alloy fasteners meet the neutral salt spray test for 96h without white rust, and all exposed fasteners are made of 304 stainless steel.

(11) Zinc-nickel alloy fasteners should not be used in conjunction with stainless steel.

(12) The anchor hole for the installation of the ev car charging post shall be pre-processed, and the hole shall not be drilled after the charging pile is placed. The inlet hole at the bottom of the charging pile should be sealed with fireproof mud to prevent surface moisture from entering the pile from the inlet hole. After installation, silicone sealant can be applied between the pile and the cement installation table to strengthen the sealing of the bottom of the pile.

After reading the above technical requirements and anti-corrosion design of the sheet metal charging pile shell, now do you know why the price of the charging pile with the same charging power will be very different?

Media Contact

Company Name: China Beihai Fiberglass Co., Ltd.

Email: Send Email

Country: China

Website: https://www.fiberglassfiber.com/