USA – Factory inefficiencies can reduce production, increase errors, and reduce overall profit margin. Pico MES addresses these major problems for small and mid-sized factories through its software solution. Leveraging the software solution provided by the company, factories can now boost their efficiency and productivity, reduce errors, and overall boost their profit margins.

Pico MES understands the importance of its software solution in helping more factories break even and make more profit. The company has, therefore, offered the solution at the right price that won’t break the factory’s pocket or bank. It has also ensured that the software solution won’t cost factories any further by eliminating the need for consultants or specialized programmers. With the solution, factories will only pay for what they need and when they need it, allowing them the flexibility and control needed to improve their business operation in all areas.

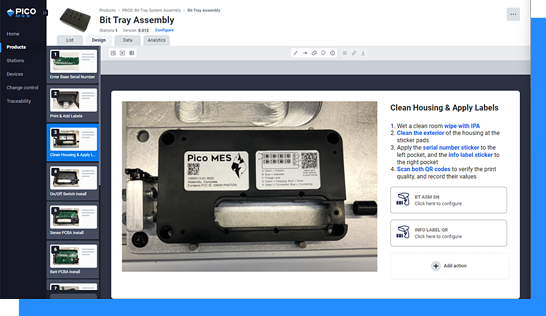

Describing the software solution and how it works, the MES vendor’s spokesperson, Ryan Kuhlenbeck, noted that Pico runs locally to match each factory’s infrastructure with the benefits of cloud backup and support. He added that the factory operating system is easier to set up and use, offering a plug-and-play solution that enables a station-by-station view of the factory as well as all data, including the bottlenecks, inefficiencies, downtime, and others.

Using the solution, small and medium factories will enjoy visual worker guidance with easy-to-follow, clear work instructions with images that provide additional clarity. The software solution also offers factory owners and operators a chance to connect their tools, thus eliminating the need for operator control checks. With the Manufacturing Execution System, users can also enjoy consolidated data, traceability, and more.

Pico MES describes the many associated benefits of using its software solution to include universal availability, which means that any device can be incorporated and made available in the manufacturer’s device library, allowing them to purchase a wide range of tools needed to boost their production process. Clients can also expect to enjoy a faster throughput as connected tools don’t require an operator to take the time and check their work as is already done for them. The software solution also offers improved yield as all systems are properly connected, and errors are significantly minimized.

Leveraging the automated backup solution included in Pico MES, clients can stay updated, in real-time, with their data, spot errors, and enjoy improved efficiencies. Get in touch with Pico MES via their website to get started.

Media Contact

Company Name

Pico MES

Contact Name

Ryan Kuhlenbeck

Address

National Campaign

City

San Francisco

State

CA

Postal Code

94115

Country

United States

Website

https://www.picomes.com/